Project 1 Mansilla + Tuñón Architects

Building Information for a case

study

León, Spain

2004

This

playful concert hall occupies the south side of a large plaza in León’s

historic center. Although conspicuously modern in contrast to the

sixteenth-century Monastery of San Marcos nearby, the building responds to the

traditions of its environment with sensitivity. Boasting a museum and music

venue, its purpose is to revitalize the cultural life of this Spanish regional

capital.

The

white latticed façade is composed of five horizontal levels that reference a

musical score, the vertical rectangular apertures resembling the notes. The

apertures are a series of deeply recessed windows of various sizes that capture

the daylight and filter it into the internal spaces. The pockets of

illumination created by these openings cast changing shadows that animate the

entrance foyer behind the façade and echo the way light pervade the nearby

Gothic cathedral. The building is composed of two separate wings: the

square-facing volume housing three floors of exhibition halls and an angled

wing at the east end housing the auditorium.

The

public entrance makes the divide between the blocks and a long ramp leads to

the exhibition areas. These gallery spaces give the building a purpose beyond

musical performances. The auditorium can be adapted for different events with

movable seats and acoustic panels. Lines of cylindrical lights are suspended

from the ceiling shells, illuminating the luxurious interior, lined with ribs

of dark wenge wood. The darker tones of the auditorium contrast starkly with

the luminosity of the entrance and exterior, where the light external walls

give on to pale wood floors and paneling. Administrative spaces run along the

southern edge of the auditorium whilst technical facilities and rehearsal rooms

are accommodated underground.

Reference

Toler,

P. (2016). Inventions in Architecture: From Stone Walls to Solar Panels.

Cavendish Square Publishing, LLC.

Figure 1. Reference link to the photo above:

Figure 2. Reference link to the photo above:

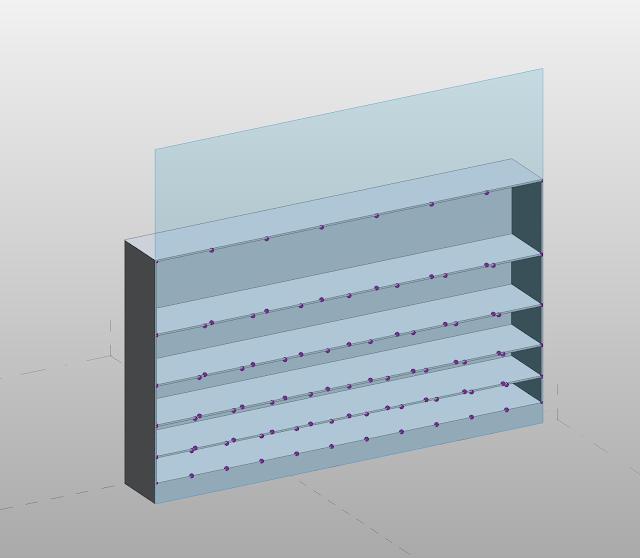

The parametric, conceptual mass family for my project

Building dimensions

Table 1 shows the dimension of openings in different levels.

Table 1. Information regarding openings

Openings’ level

|

No. of openings

|

Openings’ height

|

Openings’ width

|

1

|

11

|

170”

|

252”

|

2

|

10

|

200”

|

277.2”

|

3

|

9

|

260”

|

308”

|

4

|

8

|

330”

|

346.5”

|

5

|

7

|

490”

|

396”

|

LCM* (11, 10, 9, 8, 7) = LCM (11, 2×5, 32, 23, 7) = 23×32×5×7×11 = 27,720

*LCM: Least Common Multiple

Building length = 0.1 × [LCM (11, 2×5, 32, 23, 7)]” + 2 × wall thickness = 2772” + 20” = 2792”

Building height = 140” + 170” + 200” + 260” + 330” + 490” + 5 × ceiling thickness = 1,650”

Note: 140" is the height of the part below the first level of openings.

Building width = 396”

Mass design process

1. “Conceptual Mass” was used for creating the building’s form:

Families > New > Conceptual Mass > Mass

2. “Create Form > Solid Form” was used to create a cube with the following dimensions:

Length = 2792”, Height = 1,650”, and Width = 396”

3. Horizontal lines were used to identify the lower and upper levels of the five rows of openings. The thickness of the ceilings was considered to be 12”.

4. Vertical lines were used to identify the left and right sides of all the five rows of openings. The thickness of the wall was considered to be 10”.

5. “Create Form > Void Form” was used to create the final form

of the building. The void depth was considered to be 386” (Figure 3).

Figure 3. The building form and the surface division

Surface division process

1. For each row, a

reference line were created on the inner side of the wall, connecting the upper

level of each row to its lower level, at the right side of the building.

2. For

each row, “Offset” was used to create a reference line for the left side of

each opening based on the wide of the openings on each level (Table 1).

3. Finally, “Reference

> Point Element” was used to create points on both ends of each reference

line. The purpose of creating such point elements was to identify where the facade modules would be manually attached (Figure 3).

The parametric envelop (facade) family for my project

Module dimensions

For each row, a specific module was created using “Generic Model Adaptive:”

Families > New > English_I > Generic Model Adaptive

In other words, totally 5 different modules were created with

the same depth but with different height and width (Table 2).

Table 2. Information regarding opening modules

Opening level

|

Module height

|

Module width

|

Module depth

|

1

|

170”

|

252”

|

40”

|

2

|

200”

|

277.2”

|

40”

|

3

|

260”

|

308”

|

40”

|

4

|

330”

|

346.5”

|

40”

|

5

|

490”

|

396”

|

40”

|

Module design process

By defining different instances for each frame, we can simply

control the façade pattern in this project.

1. Size of opening frames were controlled by the following instance parameters: opening frame’s width and height.

2. Size of windows were controlled by the following instance parameters: window’s frame width and height.

3. The location of windows were identified by the following instance parameters: distance left and down.

Table 3 shows all the instance parameters and their names used

for creating the modules. It also indicates for which parameters a

formula was defined. Figure 4 shows all the formulas that were used to parametrically create facade modules.

Table 3. The name of parameters used for creating

facade modules

Parameter

|

Parameter name

|

Formula

|

Window’s height

|

WinHeight

|

✓

|

Window’s width

|

WinWidth

|

✓

|

Distance between lower levels of windows and opening frames

|

DisDown

|

✓

|

Sum of window’s height and distance down default

|

WinDownHeight

|

✓

|

Opening frame’s height

|

FrameHeight

|

×

|

Subtracting window’s height from opening frame’s height

|

FrameWinHeight

|

✓

|

The acceptable input value for the parameter distance down

|

DisDownDef

|

✓

|

The input value for the parameter distance down

|

DDD

|

×

|

Distance between left sides of windows and opening frames

|

DisLeft

|

✓

|

Sum of window’s width and distance left default

|

WinLeftWidth

|

✓

|

Opening frame’s width

|

FrameWidth

|

×

|

Subtracting window’s width from opening frame’s width

|

FrameWinWidth

|

✓

|

The acceptable input value for the parameter distance left

|

DisLeftDef

|

✓

|

The input value for the parameter distance left

|

DLD

|

×

|

Figure 4. The formulas used for parameters for creating facade modules parametrically

For creating a module for each opening level, the

following steps were taken:

1. On a vertical reference plane, a rectangle representative of

an opening frame, was created using the appropriate width and height (Table

2).

2. On each side of the opening frame, a reference line was

created and were connected to the side by means of “Align.”

3. “Aligned Dimension” was used to label the width and height of

the opening frame by the corresponding instance parameters.

4. Inside the opening frame, another rectangle representative of

the corresponding window, was drawn.

5. On each side of the window, a reference line was created and were

connected to the side by means of “Align.”

6. “Aligned Dimension” was used to label the width and height of

the window by the corresponding instance parameters.

7. “Aligned Dimension” was used to label the distance of left and

down sides of the window from the left and down sides of the opening frame,

respectively, by the corresponding instance parameters.

8. The opening frame was selected and “Create Form > Solid

Form” was used to create a cube with the depth 40” (Table 2).

9. The window on the behind surface of the cube and the opening frame

on the front surface of the cube were selected. Then, “Create Form > Void Form” was

used to create the module.

10. “Reference > Point Elements” was used to create a point

on each corner of the opening frame on the front surface of the cube.

11. Each point element was selected and made adaptive

using “Make Adaptive” (Figure 5).

Figure 5. Facade module

Finally, “Load into Project” was used to manually attach the facade modules to the corresponding point elements on the mass module (Figure 6).

Figure 6. The building facade after attaching the modules to the point elements

Since instance parameters were used for creating the facade modules, the shape of the modules could be changed in mass module (Figure 7).

Figure 7. Changing the facade modules in mass module

Figure 8. A render of the project's facade

Project movie

The project movie can be watched on the link below:

Figure 9. Screenshot 1

Figure 10. Screenshot 2

Figure 11. Screenshot 3

Figure 12. Screenshot 4

Figure 13. Rendering 1

Figure 14. Rendering 2

Thank You!

Comments

Post a Comment